Finding the Ideal Manufacturer for Best Pressure Reducing Valves in Your Industry

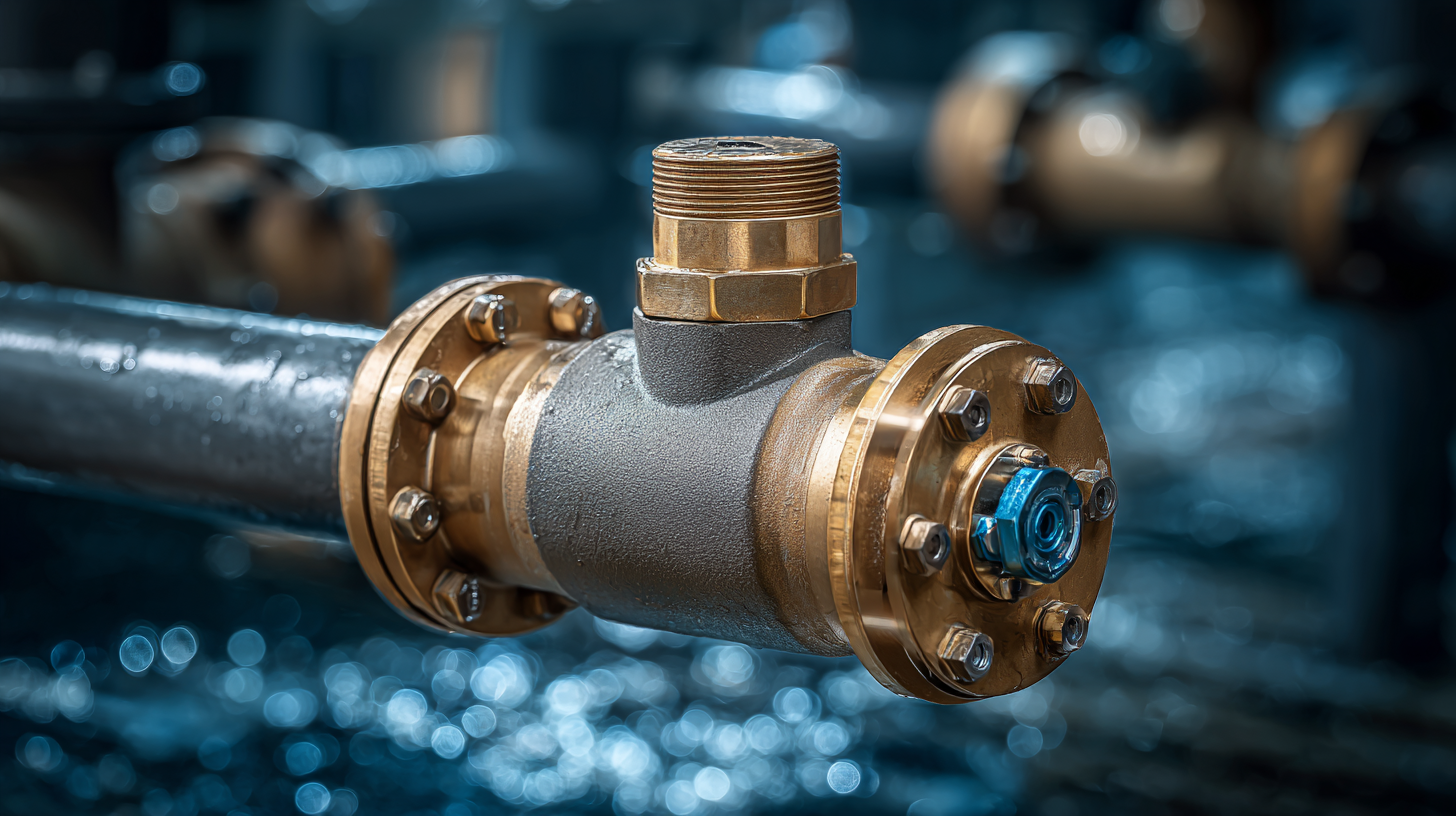

In the rapidly evolving industrial landscape, the significance of high-quality Pressure Reducing Valves (PRVs) cannot be overstated. According to a recent market analysis by Mordor Intelligence, the global pressure reducing valve market is expected to grow significantly, reaching a valuation of USD 8.94 billion by 2026, driven by the increasing demand for efficient fluid control in various sectors, including water treatment, oil and gas, and manufacturing. This surge highlights the necessity for industries to focus on finding manufacturers that prioritize quality and innovation.

With China's manufacturing prowess positioned to lead globally, sourcing PRVs from reputable Chinese manufacturers can offer industries a competitive edge, ensuring compliance with international standards while enhancing operational efficiency. In this blog, we will delve into the essential criteria for selecting the ideal manufacturer of Pressure Reducing Valves that meet your industry's specific needs, emphasizing quality and performance as paramount considerations.

Understanding the Importance of Pressure Reducing Valves in Various Industries

Pressure reducing valves (PRVs) play a crucial role in

maintaining safety and efficiency in various industries. These devices regulate the pressure of

fluids within a system, ensuring that it remains at optimal levels. In sectors such as

oil and gas, manufacturing,

and water management, the need for controlled

pressure is paramount. Unregulated pressure can lead to equipment malfunctions, inefficient

operation, and even catastrophic failures. By employing PRVs, companies can protect their

infrastructure, extend the lifespan of their equipment, and improve overall

operational efficiency.

Pressure reducing valves (PRVs) play a crucial role in

maintaining safety and efficiency in various industries. These devices regulate the pressure of

fluids within a system, ensuring that it remains at optimal levels. In sectors such as

oil and gas, manufacturing,

and water management, the need for controlled

pressure is paramount. Unregulated pressure can lead to equipment malfunctions, inefficient

operation, and even catastrophic failures. By employing PRVs, companies can protect their

infrastructure, extend the lifespan of their equipment, and improve overall

operational efficiency.

Moreover, the application of pressure reducing valves is not confined to just a few industries.

In HVAC systems, for instance, PRVs help maintain balanced

pressure, which is essential for heating and cooling efficiency. In the food and beverage industry,

these valves ensure that processes like bottling and pasteurization occur under controlled

pressure conditions, maintaining product quality and safety. As industries continue to evolve,

the significance of pressure reducing valves will only grow, highlighting the importance of

selecting the ideal manufacturer who understands the specific needs of each sector.

This choice can significantly impact operational reliability and efficiency.

Key Features to Look for in a Pressure Reducing Valve Manufacturer

When selecting an ideal manufacturer for pressure reducing valves, it is essential to focus on key features that can significantly affect their performance in various industrial applications. One of the most critical aspects to consider is the valve's ability to handle a variety of media while maintaining optimal flow characteristics. Manufacturers should provide designs that minimize noise, even under high-pressure conditions. For instance, advanced cage control valve designs can effectively reduce noise generated during operation, although they may struggle to achieve equal percentage flow characteristics.

Additionally, it's vital to evaluate the manufacturer's approach to testing and validating valve performance. Look for manufacturers that supply extensive data on valve capacity and performance metrics, as this transparency can indicate a commitment to quality. Parametric analysis and numerical studies, showcasing how structural variations influence valve efficiency, can also provide deeper insights into the manufacturer's capabilities. Robust testing methodologies not only enhance product reliability but also reassure clients of the valve's longevity in demanding environments, such as hydrogen decompression systems in fuel cell vehicles.

Pressure Reducing Valve Manufacturer Key Features

This chart illustrates the key features to look for when selecting a pressure reducing valve manufacturer, with data on the importance of various features as rated by industry professionals.

Industry-Specific Applications of Pressure Reducing Valves

Pressure reducing valves (PRVs) play a pivotal role in multiple industrial applications, ensuring safe and efficient pressure management in systems ranging from water supply to chemical processing. According to a market analysis by Global Market Insights, the demand for PRVs in the water management sector is projected to reach over $5 billion by 2026, primarily driven by the need for enhancing operational efficiency and reducing wastage.

In industries such as oil and gas, PRVs are critical for maintaining the integrity of pipelines under high fluctuations in pressure, protecting infrastructure and ensuring compliance with safety regulations.

In industries such as oil and gas, PRVs are critical for maintaining the integrity of pipelines under high fluctuations in pressure, protecting infrastructure and ensuring compliance with safety regulations.

In the pharmaceutical industry, the precision offered by PRVs becomes even more crucial. A report from Transparency Market Research highlights that the adoption of advanced pressure reducing valves can significantly mitigate the risk of contamination in sensitive processes. With strict regulatory requirements necessitating tight controls on operational parameters, selecting the right manufacturer for PRVs tailored to specific applications can directly impact product quality and operational reliability.

As this technology continues to evolve, industries must emphasize collaboration with manufacturers who not only understand their unique needs but also offer innovative solutions to keep pace with stringent industry standards.

Case Studies of Successful Deployments in Diverse Sectors

In today's rapidly evolving technological landscape, diverse industries are increasingly leaning on innovative solutions to cater to specific needs. This trend is evident in successful case studies demonstrating the deployment of pressure reducing valves across various sectors. For instance, companies are integrating advanced digital technologies and artificial intelligence to enhance operational efficiency and responsiveness. A notable example includes a leading French financial institution that applied AI-driven insights to tailor its services, ensuring that the products utilized align perfectly with the unique operational requirements.

Moreover, adoption of intelligent manufacturing and smart networks plays a pivotal role in improving the performance of pressure reducing valves. As companies navigate the complexities of digital transformation, case studies highlight how organizations have optimized their production processes by leveraging cloud-based solutions and agile methodologies. These successful implementations not only showcase the effectiveness of cutting-edge technologies but also emphasize the importance of partnering with ideal manufacturers who understand the nuances of different industry demands. This synergy fosters innovation and drives growth, proving that choosing the right manufacturer can significantly impact operational excellence in delivering high-quality pressure reducing valves.

Finding the Ideal Manufacturer for Best Pressure Reducing Valves in Your Industry

| Industry Sector | Application | Pressure Range (psi) | Material | Deployment Year | Benefits Achieved |

|---|---|---|---|---|---|

| Oil & Gas | Pipeline Pressure Control | 100-1500 | Stainless Steel | 2020 | Improved safety and reduced leakage rates |

| Water Treatment | Water Distribution System | 50-200 | Bronze | 2018 | Enhanced efficiency and lower operational costs |

| Pharmaceutical | Process Water System | 30-100 | PVC | 2021 | Reduced contamination risk and increased reliability |

| Manufacturing | Machinery Cooling System | 70-300 | Aluminum | 2019 | Increased equipment lifespan and energy savings |

| Food & Beverage | Beverage Bottling Process | 20-80 | Food-Grade Steel | 2022 | Improved product quality and reduced wastage |

Evaluating Quality and Reliability in Pressure Reducing Valve Production

When selecting the ideal manufacturer for pressure reducing valves (PRVs), one of the most critical factors to consider is the quality and reliability of their production processes. According to a recent report by Markets and Markets, the global pressure relief valve market is projected to reach USD 1.55 billion by 2026, driven by the increasing demand across various industries such as oil and gas, water and wastewater, and pharmaceuticals. As such, ensuring that your chosen manufacturer adheres to high standards in both materials and production techniques is essential to guarantee performance and longevity.

Additionally, the reliability of a manufacturer can often be gauged by their track record in the industry. Studies conducted by the Valve Manufacturers Association show that manufacturers with consistent production quality and responsive customer service see a 25% higher customer satisfaction rate. Engaging with current clients and reviewing case studies can provide insights into their operational reliability and how they handle potential issues.