Discover the Excellence of China's Leading Manufacturer: The Best Air Flow Control Valve

In the rapidly evolving landscape of industrial automation, the Air Flow Control Valve plays a pivotal role in optimizing system performance and ensuring efficient fluid management. According to a recent market analysis report by Grand View Research, the global air flow control valve market is projected to witness a substantial growth, reaching approximately USD 6.5 billion by 2025, with a compound annual growth rate (CAGR) of 6.2% from 2018 to 2025. This growth is driven by increasing demand for energy-efficient technologies and stringent regulations on emissions across various industries. As China's leading manufacturer, the best air flow control valve is not only setting quality standards but also integrating advanced technologies to meet the diverse needs of the market. This blog will delve into the unique offerings of top manufacturers, the latest innovations in air flow control, and insights into the industry's future trajectory by 2025.

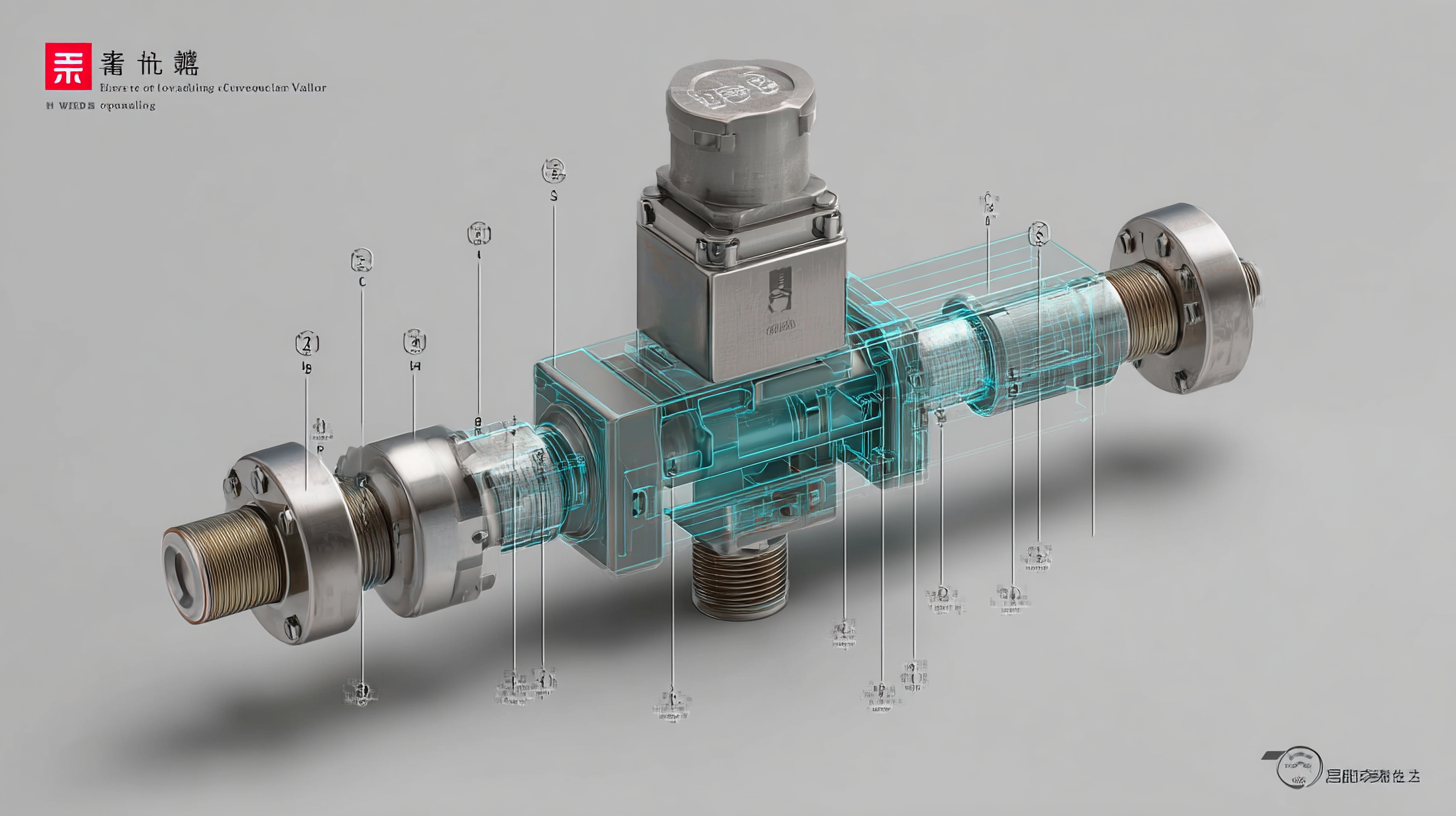

Understanding Air Flow Control Valves: An Overview of Types and Applications

Air flow control valves play a pivotal role in various industries, ensuring efficiency and regulation of fluid dynamics. There are several types of air flow control valves, each designed to cater to specific applications. The most commonly used types include globe valves, butterfly valves, and ball valves. According to a recent market report by Research and Markets, the global market for industrial valves, including air flow control valves, is projected to reach USD 88.7 billion by 2025, growing at a CAGR of 6.4%. This growth can be attributed to the rising demand for advanced fluid control systems across sectors such as oil and gas, water treatment, and manufacturing.

In addition to their types, the applications of air flow control valves are diverse. They are crucial in HVAC systems for maintaining indoor air quality and energy efficiency. A study by Research and Markets highlights that the HVAC segment alone accounts for approximately 25% of the total industrial valve market. Furthermore, air flow control valves are also extensively used in automation systems, where precise control of air flow is vital for optimal performance. For instance, in pneumatic systems, the accuracy of air flow can significantly impact productivity, underscoring the necessity for high-quality valves designed by leading manufacturers in China.

Discover the Excellence of China's Leading Manufacturer: The Best Air Flow Control Valve

| Valve Type | Material | Pressure Rating | Temperature Range | Applications |

|---|---|---|---|---|

| Butterfly Valve | Cast Iron | 150 psi | -10°C to 150°C | HVAC, Water Treatment |

| Globe Valve | Stainless Steel | 300 psi | -20°C to 200°C | Oil and Gas, Chemical Processing |

| Ball Valve | Brass | 600 psi | -30°C to 180°C | Water Supply, Food Industry |

| Check Valve | PVC | 150 psi | 0°C to 60°C | Drainage, Irrigation |

| Solenoid Valve | Aluminum | 100 psi | -10°C to 80°C | Automation, HVAC |

Common Issues Faced with Air Flow Control Valves and How to Address Them

Air flow control valves are essential components in various industrial applications, but they often encounter common issues that can hinder performance. According to a recent market analysis by ResearchAndMarkets, improper installation and wear and tear are leading factors causing failures in these devices. More than 30% of users reported inconsistent flow rates, highlighting the need for regular maintenance and immediate troubleshooting to ensure efficiency.

To tackle these issues, regular inspections are crucial. Operators should monitor valve performance, checking for signs of wear or leakage. Additionally, implementing a preventive maintenance schedule can reduce the likelihood of malfunctions. For example, lubricating moving parts and replacing worn seals can significantly extend the life of an air flow control valve.

**Tips:** When selecting a valve, ensure compatibility with your system's specifications. Always opt for high-quality materials to improve durability. Remember, proper installation practices can prevent up to 25% of flow control problems before they arise.

Innovative Solutions by China's Leading Manufacturer for Air Flow Control Problems

China's leading manufacturer is at the forefront of addressing air flow control challenges through innovative solutions. In sectors where precise air flow regulation is crucial, such as the pharmaceutical, food and beverage, and marine industries, these advanced air flow control valves play a pivotal role. With the growth of industries reliant on optimized process flows, the demand for effective air flow control solutions has surged, making them essential components in ensuring operational efficiency and product quality.

The market for turbo chillers, categorized by cooling type—water-cooled and air-cooled—and by cooling capacity—small, medium, and large—is also expanding. Industry analysts predict a significant increase in the adoption of these systems across various applications, driven by the need for energy efficiency and stringent regulatory standards. As industries evolve, manufacturers who prioritize innovative design and reliability will likely lead in capturing market share and addressing the escalating demands for cooling solutions across diverse sectors.

Quality Assurance: Why Choose a Trusted Manufacturer for Air Flow Control Valves

When it comes to air flow control valves, quality assurance is paramount. Choosing a trusted manufacturer ensures that the products meet stringent standards, leading to improved efficiency and longevity. According to a recent report by MarketsandMarkets, the global market for air flow control devices is expected to reach $6.5 billion by 2025, driven by the increasing demand in industries such as HVAC, automotive, and manufacturing. A reputable manufacturer not only adheres to quality control measures but also utilizes advanced technology to create innovative products.

Tips: When selecting an air flow control valve, consider the manufacturer's certifications and testing procedures. A manufacturer with ISO 9001 certification indicates a commitment to quality management standards. Additionally, inquire about their warranty policies and customer support services, as these reflect the company’s confidence in its products.

Moreover, investing in high-quality air flow control valves can significantly enhance system performance and reduce energy consumption. A study conducted by the American Society of Mechanical Engineers highlights that efficient air flow control can lead to a reduction of energy costs by up to 30%. Hence, partnering with a reliable manufacturer not only assures you of superior products but also translates into cost savings in the long run.

FAQS

: Industries such as pharmaceuticals, food and beverage, and marine sectors benefit significantly from advanced air flow control solutions.

A trusted manufacturer ensures that air flow control valves meet stringent quality standards, leading to improved efficiency and a longer lifespan of the products.

The global market for air flow control devices is expected to reach $6.5 billion by 2025, driven by increasing demand in various industries such as HVAC, automotive, and manufacturing.

When selecting an air flow control valve, consider the manufacturer's certifications, testing procedures, warranty policies, and customer support services.

Quality control measures are crucial as they ensure that products meet specific standards, which improves operational efficiency and product reliability.

Investing in high-quality air flow control valves can enhance system performance and reduce energy consumption, potentially cutting energy costs by up to 30%.

Consumers should look for manufacturers with ISO 9001 certification, as it indicates a commitment to quality management standards.

The market for turbo chillers is categorized by cooling type (water-cooled and air-cooled) and by cooling capacity (small, medium, and large).

The expansion of the turbo chillers market is driven by the need for energy efficiency and compliance with stringent regulatory standards.

Partnering with a reliable manufacturer assures superior product quality and translates into long-term cost savings through improved system performance and reduced energy consumption.